The sequencing of the entire human genome

back in the early 2000s is considered one of the most important scientific

breakthrough enabling data-driven medicine.

It flooded researchers in biology with a

tremendous amount of Big Data that needed to be processed and tested. It was

around then that DNA microarrays, small glass chips where thousands of DNA

fragments are deposited, became popular because they enable high-throughput and

multiplexed testing for gene expression and mutations, for example in cancer.

|

| From left to right, Julien Cors, Govind Kaigala and David Taylor |

Interestingly, DNA and protein microarrays were one

of the convergence points of microtechnology and biology that resulted in the

fabrication of high-density arrays of biomolecules.

While protein microarrays have significant value for drug discovery, and

molecular profiling, the same success in the use of DNA arrays was not

transferable to protein arrays due to the limited quality of protein arrays.

This inspired a team of IBM scientists

to develop a new biopatterning method for efficient, accurate and high-quality

patterning of proteins on surfaces by addressing fundamental bottlenecks

inherent to the fabrication of protein microarrays. Such high-quality

microarrays will benefit quantitative biological assays for personalized

diagnostics and screening applications.

A new paper appearing this month on the

cover of Analytical

Chemistry details their latest research breakthrough. I spoke with two

of the authors Govind

Kaigala and Julien

Cors.

|

Cover of Analytical Chemistry

Credit: ACS Publications |

One of the benefits of your technique is depositing

reagents on surfaces in a wet environment. Why is this important and how does

it compare to current approaches?

Govind Kaigala (GK): Current techniques for protein patterning use

inkjet and pin spotters, and they do not produce homogeneous protein patterns

-- largely because they operate in a dry environment.

So we asked ourselves, biology is wet, so how

can we accurately test samples when we are changing it’s make up by drying it

out?

In contrast, our method relies on a microfluidic

probe (MFP) that confines nanoliter volumes of reagents in a wet

environment. By fully immersing the substrate in a liquid, the “coffee

stain effect” (Marangoni

effect), is minimized with the reduction of evaporation. In

addition, we use continuous flows on the surface, which ensure improved reaction

kinetics compared to deposition relying on diffusion in existing techniques.

Also via a technique of re-circulating liquid we improve

reagent utilisation, which is important because its very expensive.

In our article we studied the

transport of biomolecules in flows and their surface interactions and to

address this we designed specific MFP heads to create homogeneous protein

patterns with volume consumption comparable to inkjet spotters.

The paper also describes the

convection-enhanced transport and recirculation of sub-microliter volumes using

analytical models.

A major factor of your research is working at the

micrometer level. Can you explain what the trick is when working with such

small sample sizes?

Julien Cors (JC): IBM is considered the birthplace for

scanning probe techniques with the original scanning probes developed for

atomic imaging. Our scanning probe isn’t imaging atoms, the MFP technology that

we are developing is for biological applications, in this case protein

patterning. But, the technique is similar in that the probe head never comes

into contact with the sample and is used in liquid environments and with a

resolution of a few micrometers.

By continuously injecting and

aspirating liquids, nanoliter volumes of liquids are confined at the tip of the

head. To put this into perspective, we are working with volumes of liquids

thousands of times smaller than a tear drop.

At this micrometer-length scale both reaction

kinetics and transport of biomolecules onto the surface are

highly favourable By exposing one or multiple such confined liquid

using the probe on a surface diverse patterns of biomolecules can be created.

Can you talk about some specific applications for

the innovation?

GK: Protein-based assays

(immunoassays) are very broadly applicable, and our method can be used to

create high-quality substrates to implement such tests.

Current protein microarrays provide

qualitative information i.e. presence or absence of a specific biomarker.

Because of the inhomogeneity of the deposited patterns, extracting quantitative

information remains challenging. Quantitative data have great importance both

in diagnostics and biomarker discovery.

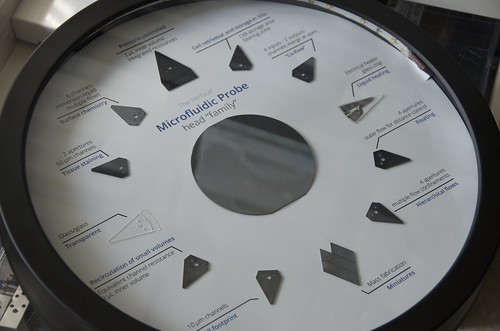

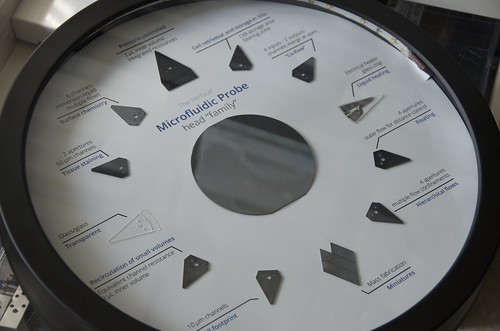

|

The MFP comes with different microfluidic

patterns based on the type of application. |

For example, in the Analytical Chemistry paper we demonstrate an

assay for the detection immunoglobulins (IgGs). IgGs are used as a diagnostics

marker for several autoimmune diseases and as a measure of the immune response.

This

research is partially funded by your European Research Council (ERC) grant.

What do you hope to achieve by the end of the grant?

GK: Within the ERC-BioProbe project, we

are developing new concepts, tools and methods for improved molecular profiling

of tissues for tumor diagnosis for personalized medicine.

Techniques for liquid recirculation and analytical models for

improved protein microarrays was in fact an off-shoot of this work – while in

BioProbe, we will focus on the main theme, we keep an eye for such projects and

pursue them.

What's

next for your research and when can we expect it to be used outside of IBM by

partners?

GK: We are very excited about the progress and evolution of the

microfluidic probe, particularly as it is now starting to be applied in various

areas including pathology and personalized medicine.

Labels: healthcare, IBM Research - Zurich, microfluidic probe